Exterior painting and cleaning

Illuminations and Signage

Gardens and Bridges

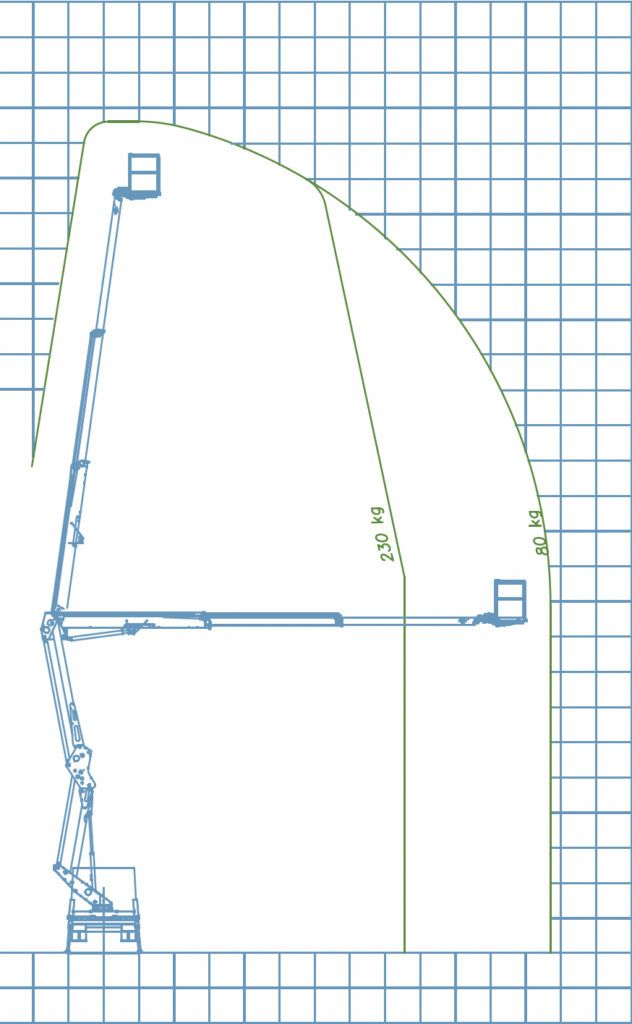

ARM: Telescopic arm with synchronized exit manufactured with high strength steel profiles (SPP), which guarantees greater performance and has a lower weight than conventional steel. The profiles are cold shaped with a single laser welding for minimal alteration of the quality of the material. The cataphoresis treatment allows for a greater degree of protection and resistance to corrosion.

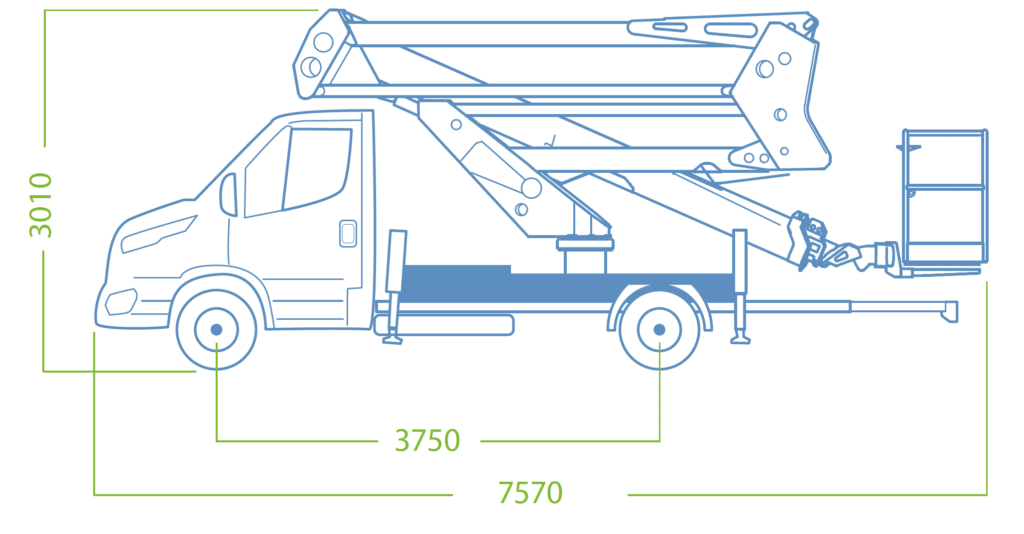

STABILIZERS (H+H): Four fixed vertical stabilizers with independent controls and automatic operation from a single button. The vertical stabilizers, which do not protrude from the vehicle, facilitate the stabilization maneuver and do not damage the support surface. The extra travel allows for greater ability to overcome surface irregularities and greater speed in stabilizing the platform.

SPEED H+H AUTOMATIC STABILIZATION: Stabilization system with electronic leveling device that allows you to stabilize correctly at 0°, overcoming irregularities in the ground simply and safely with just a button, even from the basket.

CONTROLS: Electro-hydraulic controls present on the base of the frame and on the basket. In the basket the controls are high precision and ergonomic. The console incorporates the new Socage security system for maneuver consent, Socage Security System, which prevents involuntary operations by the operator. It also incorporates a complete system of high visibility multi-coloured LED lights which guarantee better and greater information and assistance to the operator.

BASKET: made of aluminum (dimensions 1400x700X1100 mm) with load capacity for two people, front access for greater protection of the operator(s) and integrated safety bar to protect against involuntary manoeuvres. Rotation of 90° right + 90° left by means of a hydraulic rotation system.

BASKET LEVELING: Automatic leveling system using compensated cylinders, with the possibility of manual recovery if necessary.